How To Choose the Right Air Pressure For Your Tires

Weight

Vehicle weight is one of the most significant factors for how much air pressure you need to run in your tires, both on the road and off. Heavier vehicles, such as 3/4 or 1-ton trucks, require much more air to support them than a lightweight Jeep or Tacoma. Running 10 psi in a one-ton diesel truck may cause the rim to touch the ground. But the same pressure in a Suzuki Samurai might not even cause the sidewall to bulge.

Airing down too far has several risks. The tire could come off the rim, or the wheel could touch the ground and cut the tire. At low pressures, the tire could overheat to the point of failure if underinflated on the freeway.

Tire Construction

Related to vehicle weight is the construction and load rating of the tire. Load Range C tires can’t support as much weight, or handle as high of pressures, as a Load Range E tire. The load range should be appropriate for the vehicle. You wouldn’t want to run a Load Range C tire on a heavy tow rig. But you might run a Load Range E tire on a Jeep. The typical built JK weighs around 6,000 pounds. A single Load Range E tire can carry over 3,000 pounds at maximum pressure. You wouldn’t run the Load Range E tire on the Jeep at the maximum inflation pressure listed on the sidewall (80 psi for a Load Range E tire). Since you only need the tire to carry half that much weight, running 40 psi instead of 80 psi on the street is a good starting point.

Often a given tire is only offered in one load range for a given size. So, if you want to run a 37-inch Toyo Open Country M/T on your Jeep, it’s going to be a Load Range E tire. The upside to a higher load range is that the sidewall construction is more robust. These tires tend to be both stronger and heavier. You will likely have to run less air pressure in a Load Range E tire to get the same contact patch as you would from a Load Range C tire.

There is no such thing as too low of air pressure in the snow. The idea is to maximize the contact patch size for lots of floatation. The trick is not to go too low as, even with beadlocks, you can still lose a bead. Make sure to have an air source and ratchet strap to be able to reseat a bead.

This Nitto Ridge Grappler is 12.5-inches wide and mounted on a 9-inch wide wheel. On this 4,500-pound Toyota, the tire conforms to the rocks nicely at 10 psi despite being a Load Range E tire. Much lower and we risk getting a pinch flat. This happens when the rim cuts through the sidewall when it contacts an obstacle.

Wheels

Wheels are available in a variety of diameters and widths. The larger the diameter the rim, the less sidewall there is for a given tire size. Larger diameter rims must be run at higher pressures to ensure that the rim doesn’t cause a pinch flat. This happens when the wheel cuts the tire on an obstacle.

Width is just as important. A narrower rim will retain the tire bead at low pressure better than a wider rim. This better retention is because the tire bulges out more with a narrower rim. A 35×12.50R15 tire on a 15×8 rim could use a pressure as low as 10 psi on a typical trail rig without the tire coming off the wheel. A 35×12.50R20 tire on a 20×12 wheel would need to run at least 20 psi on the trail to be safe.

More traditional beadlock wheels physically clamp the outer bead of the tire between two rings. This clamping prevents the tire from coming off the rim. The clamp holds the bead onto the wheel regardless of air pressure. A downside is beadlocks are heavier and require you to regularly check bolt torque. Other options include Method’s Trail Series wheels with a serrated bead retainer inside the wheel to grip the tire and keep it from coming off the rim. They are not as effective as a beadlock but do help retain a bead.

Lower air pressure is useful in the sand to lower the contact pressure and help the vehicle float rather than sink. We usually air down for the sand until we can visually see the sidewall start to bulge and then make the pressure match for all four corners. Go too low, though, and you risk the tire coming off the rim during hard cornering.

On Road

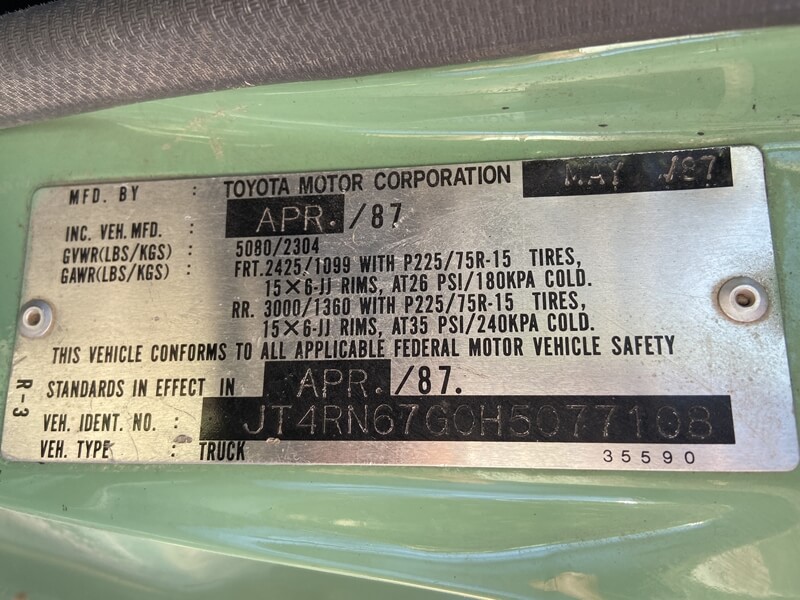

On the street, the door card is a good starting point for how much pressure to run. Remember, that air pressure suggestion is for the OEM tires. Oversized tires with a different load rating from stock will likely require less air pressure on the street. To maximize tire wear, you want the tread to be even across the ground. Too little air pressure will reduce fuel mileage. But too high of air pressure will wear out the middle of the tread prematurely.

A narrower wheel is useful to keep the tire on the rim. But they can make it difficult to achieve even wear across the face of the tire. Narrow wheels often cause the tire to crown at street pressures over 30 psi. Finding the right pressure will require some trial and error. Make small adjustments. Don’t assume that all your tires will need the same pressure unless your rig is perfectly balanced from front to back. If you are confused, a great place to start is where you are having your tires mounted and balanced. The experts at your local 4 Wheel Parts store are a great resource too.

Off Road

The pressure you run on the trail will depend on vehicle weight, tire construction, and wheel size. Even on smoother dirt roads, lowering air pressure so the tire conforms to the terrain and improves the ride is valuable. Start by reducing the air pressure by 10 psi and fine tune from there. Rock crawling is slower, so less air pressure is required. 15 psi is a good starting point in the rocks for most Jeeps and similar 4x4s. In snow and sand, we run as little pressure as possible to allow the tire contact patch to grow.

With beadlock wheels, we will go down to 5 psi in the snow and sand. However, without beadlock wheels, we typically stay above 10 psi to ensure that the tire remains on the wheel. For full-size trucks, we run about 5 psi more pressure in every terrain, with or without beadlock wheels. This extra pressure helps support the weight of the heavier vehicle. Once back on the road, always remember to air your tires up to the proper pressure. If you don’t air back up, the tires can overheat and possibly fail.

2