When you added a lift and larger diameter tires to your 4×4, you probably noticed that the bigger tires sapped some power from your steed. That lack of power is especially noticeable while towing, climbing grades, or hauling a load of cargo. The most reliable and cost-effective way to regain that lost power is to regear the axles and match the ring and pinion gear ratio to the new tire diameter. Automotive manufacturers spend millions of dollars testing and marrying an engine in a specific application to the proper transmission and axle ratios. Adding larger tires throws this engineered combination off.

Many people make the mistake of adding power mods to a 4×4 with bigger than stock tires. They hope to counter the perceived power loss. In most case, the engine will have to work harder outside of its proper rpm range. Fortunately, most popular 4×4 axles have many different aftermarket gear ratios available to compensate for a variety of tire sizes. What axle ratio you should choose will depend on your 4×4 and several other factors. Read on to learn more about how to regain the power your big tires stole from you.

Taller than stock tires alter the final drive ratio of your 4×4 at the tires and effectively decrease the power you can put to the ground. The bigger the tires are, the more noticeable the change. The added weight and wind resistance also tax the engine.

Any power modification short of an engine swap or a supercharger installation will do little to correct the gearing problem caused by larger tires. A ring and pinion gear swap is the most cost-effective solution to the perceived power loss caused by big tires.

Why Do I Need Gears?

Every vehicle has a calculated final drive ratio that is dictated by the transmission and axle gear ratios. Vehicle manufacturers optimize the final drive ratio for overall vehicle performance and fuel economy. Increasing the tire diameter of a 4×4 effectively reduces the final drive ratio. This reduction essentially decreases the leverage your engine has to put power to the ground. It also causes the engine to operate outside of its optimum rpm range, resulting in reduced fuel economy and sluggish performance. Think of the axle gears as a lever used to move an object. It’s easy to understand that a longer lever (lower ratio gears) will do more work with the same input when compared to a shorter lever (higher ratio gears). The easiest and least expensive way to bring the final drive ratio of a 4×4 back to or near stock is via a ring and pinion swap in the axles.

Can’t I Just Add More Horsepower?

Adding horsepower can compensate for slightly larger diameter tires. But basic power adders generally can’t compensate for tires that are three sizes or larger than stock. More power doesn’t correct the final drive ratio like a ring and pinion swap. A power upgrade also won’t fix things like transmission shift points, which are incredibly crucial for transmission longevity and durability. Dollar for dollar, no performance part will make as big a difference in overall power and drivability as matching up the axle ring and pinion ratio to the tire diameter.

Gearing charts such as this can help you select the right ring and pinion for your application by matching up tire size, the gear ratio, and engine rpm. You can also simply increase your current gear ratio by the same percentage that you increased your tires.

In some applications, you might choose to go with lower gears than usual. Vehicles that spend most of their time in the dirt, haul heavy loads, commute around town, or remain on twisty mountain roads will benefit from lower gears.

How Do You Pick The Right Gear Ratio?

There are several ways to select the correct ring and pinion ratio. Many methods involve some basic math, formulas, and even charts. But the easiest way to figure out the right ratio is to lower it the same percentage you increased the tire diameter over stock. For example, imagine your 4×4 came from the factory with 32-inch tires and 4.10 axle gears. Upgrading to 37-inch tires would calculate to about a 16 percent increase in tire diameter. Increasing the 4.10 axle ratio by 16 percent would dictate the need of a 4.75 axle ratio to match the 37-inch tires. The exact axle ratio you need probably won’t be available, so it’s okay to round up when selecting the right ring and pinion. In this case, a 4.88 axle ratio would be acceptable. If math isn’t your best subject, don’t worry, there are charts available to help you choose the right axle ratio. Your local 4 Wheel Parts salesman can help you pick the correct ratio for your application too.

Can I Go With A Lower Gear Ratio Than Recommended?

The exact ring and pinion axle ratio you need for your application is always open to interpretation and can vary depending on how you use your vehicle. If your 4×4 spends a lot of time driving on long open highways, you’ll likely want to stick with matching the tire diameter and axle ratio percentages. This is mostly done to manage engine rpm and preserve fuel economy and engine longevity. If your 4×4 spends most of its time in the dirt, commuting around town, towing, or on twisty roads, choose to go with a slightly deeper axle ratio than recommended. A deeper axle ratio will make your 4×4 more peppy around town and off the line. But it will increase the rpm at a given speed when on the open road. Using the same example from above, rather than going with 4.88 gears, someone looking for a deeper gear ratio might choose 5.13 or even 5.38 gears for more punch. The deeper gears also help to compensate for increased wind resistance, heavier tires and wheels, and the weight of any accessories. In other words, if you plan to load your 4×4 down with gear and equipment regularly, you’ll want to error on the side of deeper axle gearing.

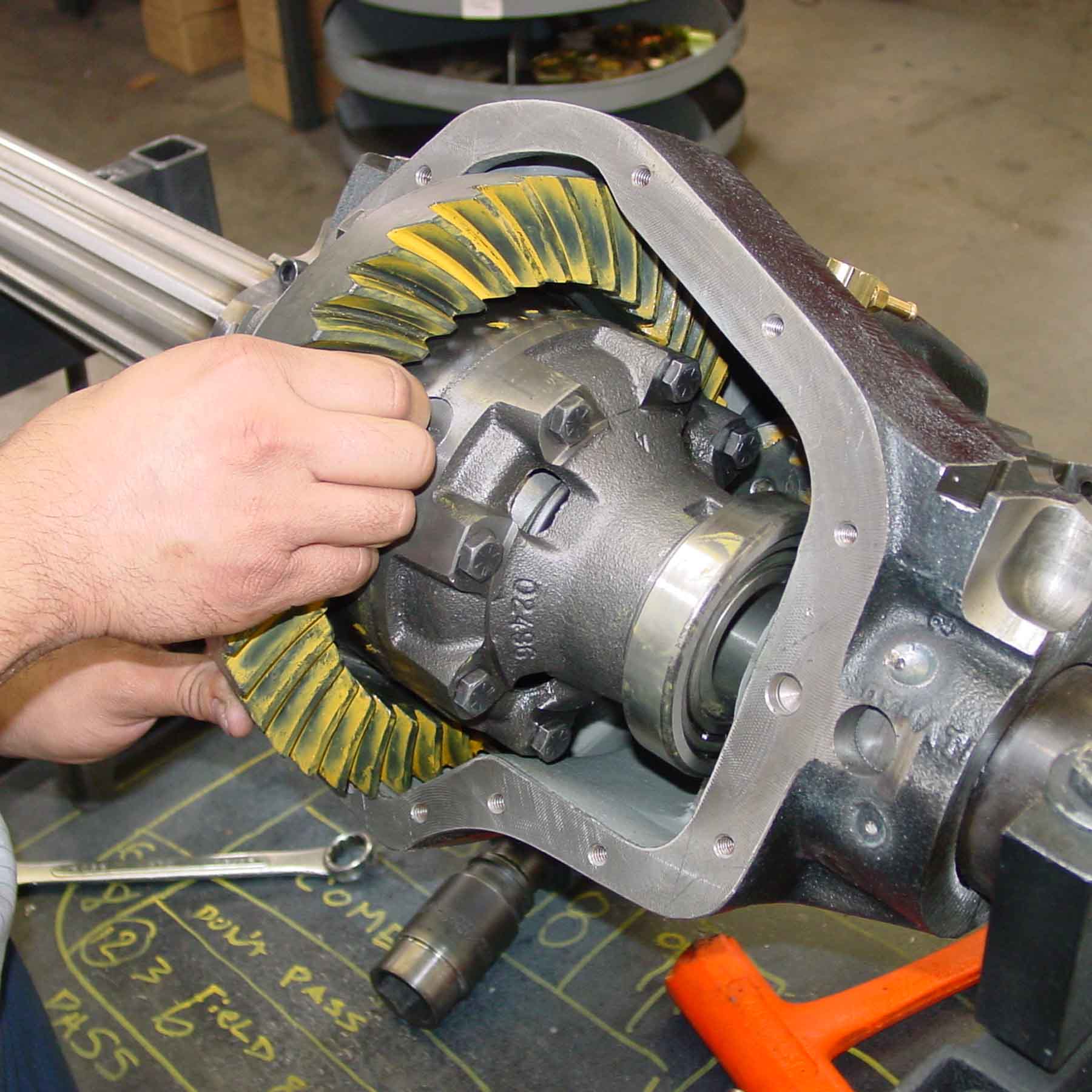

Use a full install kit when regearing an axle regardless of how new the vehicle is. Used bearings may be worn and can sometimes be damaged when removed from the old gears. Since you’re already digging into the axle, it’s also a perfect time to consider adding aftermarket axle shafts, lockers, or differential covers.

Installation is typically not a good do-it-yourself job. It requires specialty tools and knowledge. An improper gear pattern or incorrect preload can lead to unwanted axle noise along with short gear and bearing life. The good news is that your local 4 Wheel Parts store has skilled mechanics that can install gears for you.

What Other Modifications Should I Consider?

Modern 4x4s have engine and transmission computers that tap into many variables to optimize vehicle performance. One of these variables is vehicle speed. If the inputted vehicle speed is incorrect, the computers will not know the best time to shift the transmission or the proper fueling and timing the engine should have at a given rpm. Whenever you alter the tire size or gear ratio, you should also correct the speedometer. Aftermarket controllers are available to compensate for different tire sizes and gear ratios. They typically plug into the OBDII port under the dash and are a simple modification that will improve overall performance and could help increase transmission and engine longevity.

Regardless of how new your 4×4 is, it’s always a good idea to install new bearings with your fresh ring and pinion gear sets. Complete install kits are available for every popular axle. These kits include the bearings, shims, spacers, hardware, seals, and other components that the installers need to make the ring and pinion swap in your 4×4.

Since you are already digging into the axles, now is an excellent time to consider installing other axle upgrades to save on labor costs down the road. Some components to consider are stronger aftermarket axle shafts and traction-adding devices such as limited slips and locking differentials. Heavy-duty, rock-resistant differential covers can be installed to protect the differentials on trail rigs. Finned aluminum differential covers with increased oil capacity can be installed on tow rigs to help dissipate the heat generated when towing heavy loads.

Can I Install Gears Myself?

In most cases, a ring and pinion installation is not an easy at home job to be tackled by a shade tree mechanic. Only someone with experience installing gears should perform a ring and pinion installation. The installation requires several specialty tools and knowledge of bearing preload and proper gear patterns. An improper gear pattern or incorrect bearing preload can lead to unwanted axle noise and short gear and bearing life. Fortunately, your local 4 Wheel Parts store has skilled mechanics that have both the tools and expertise to install new gearsets in your 4×4 axles.

2