When you are looking for new tires for your 4×4, the first thing you are drawn to is likely just how big and aggressive a tire is. Tires vary in more than just size and tread pattern, though. There are many different factors that make up a tire. Each and every one will affect how well it works for your given application. Did you know though that a bevy of information regarding everything from the tire’s construction to how well it will wear to when and where it was made can be found right there on the sidewall? Time to get out your magnifying glass and start to read the fine print. Let’s go through all the valuable information that can be found right on the sidewall of your tires.

Floatation sizing is pretty easy to grasp. The first number indicates the tire’s diameter in inches (in this case 35 inches tall). The next number (12.50) is the width and the “R” that follows indicates that this is a radial tire. The last number (20) is the wheel diameter in inches. LT denotes that it is a light truck tire, as opposed to a passenger (P) tire. Like we said, pretty easy.

Metric sizing is more complicated to decipher than floatation sizing. This tire is 305mm wide and the sidewall is 65% of that width. R denotes that it is a radial tire, and the rim diameter is 17 (this is still in inches for some reason). So the larger the first number, the wider the tire is. The higher the second number is, the taller the sidewall is.

Sizing

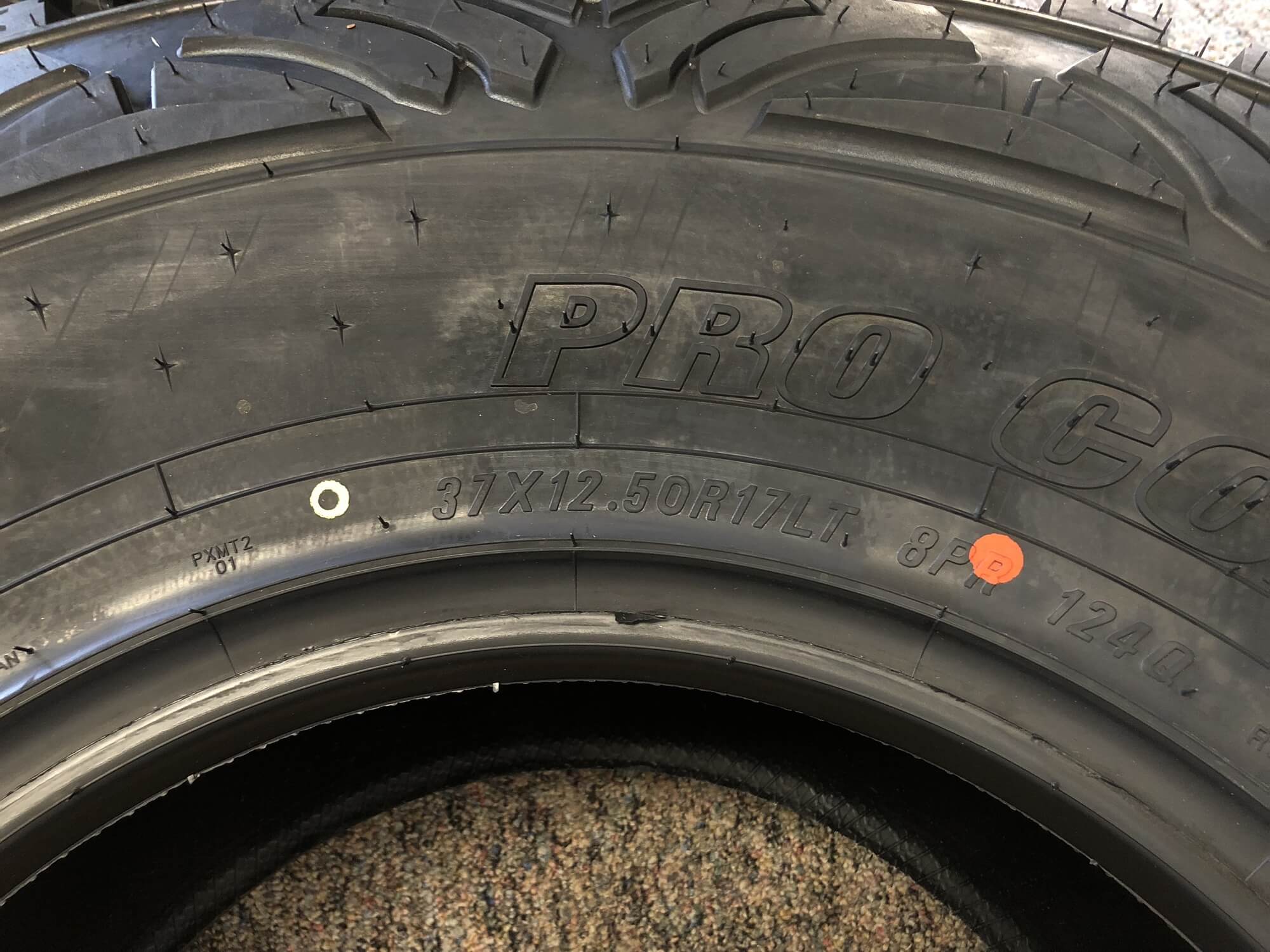

We will start with sizing since that is the first thing most people are concerned about. Imperial (commonly referred to as inflation) sizing is pretty straightforward. A 35×12.50R17 tire is 35 inches tall (approximately), 12.50 inches wide, and fits on a 17-inch rim. Note that all tires tend to measure smaller than they are actually labeled, and the amount varies by model and manufacturer.

Metric sizing is quite a bit more complicated. A typical tire size would be something like LT285/75R17. In this example, the “LT” denotes this as a light truck tire as opposed to a passenger car tire (indicated by a “P”). “285” is the section width in millimeters. The larger the number, the wider the tire is. “70” is what is called the aspect ratio, which means that the sidewall is 70% of the section width (our 285 number from earlier). 17 is the rim diameter that, oddly enough, is still listed in inches for some reason. To calculate a metric tire’s height in inches, you use the following formula:

(Section Width X Aspect Ratio / 2540 x 2) + Wheel Diameter

For example with a 285/75R17 tire, our formula would look like this:

(285 x 75 / 2540 x 2) + 17 = 33.8

It is a relatively simple equation, but if math isn’t your jam you can always look up the tire size on the manufacturer’s website. Most list detailed specifications for their tires including the exact sizes.

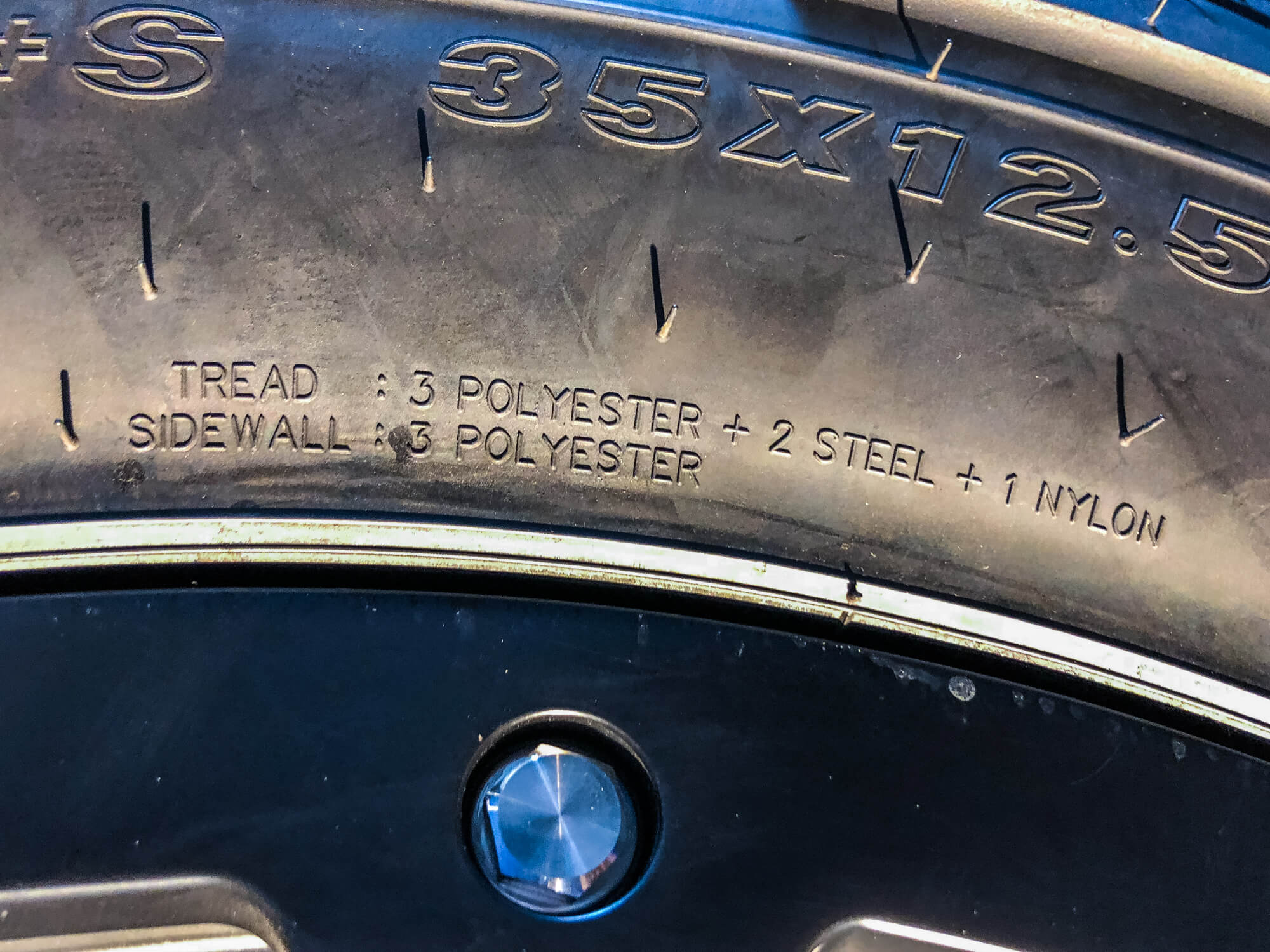

Construction

Radial construction is the most common in new tires, but bias ply tires are still offered for hardcore off-road use. Radial tires use steel belts that travel around the radius (thus the name radial) of the tire carcass at a 90-degree angle to the center of the tire. Additional belts are typically made of polyester or nylon. A radial tire allows the sidewall and the tread to function as two independent features of the tire. As a result, the ride quality and tread life tend to be better on a radial tire when compared to a bias ply tire.

Bias ply tires use nylon belts oriented at a 30-45 degree angle of the tread centerline running all the way from bead to bead for the same construction and thickness on both the sidewall and the tread surface. This results in a very strong, puncture resistant sidewall. The drawback is that bias ply tires tend to be heavy, are stiffer than comparable radial tires, and can flat spot in cold weather and when sitting for extended periods.

Deciphering if a tire is a radial or a bias play by the sidewall is relatively easy. Both metric and flotation tires will have an R in the size of the tire (37×12.50R17 for example) denoting that they are radial tires. A bias ply tire will use a dash in place of the R on flotation sizes.

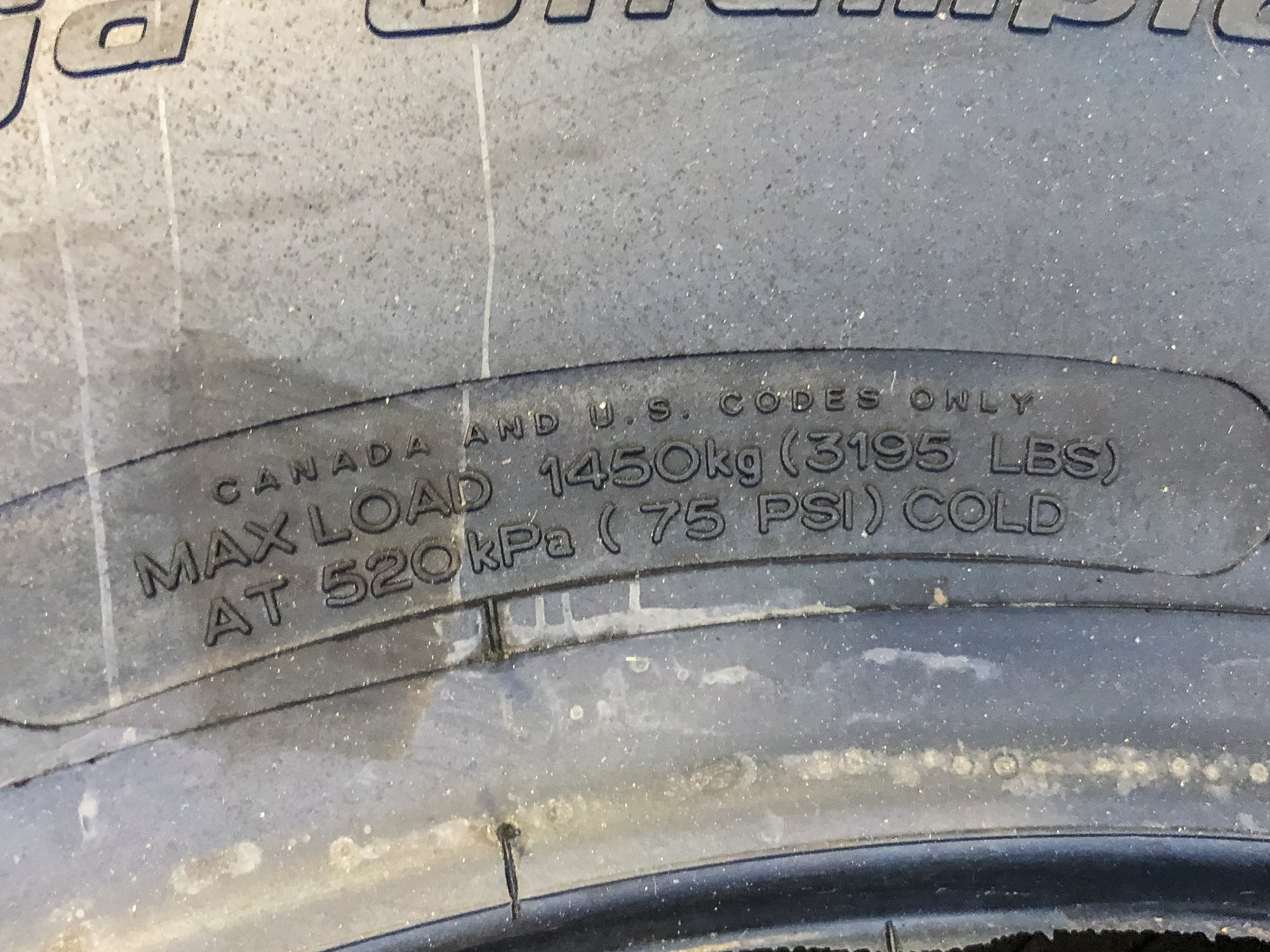

Load range is commonly thought to indicate how much weight a tire can carry. But it is more closely aligned to how much air pressure a tire can safely be inflated to. The higher the load range, the more air you can put in a tire. The more air a tire holds, the more weight it can carry without generating excessive heat.

The load capacity varies for tires even with the same load rating. More isn’t always better. If you have a relatively light Jeep, you don’t need nearly as much load capacity as a one-ton truck that is used to tow a toy hauler. Lower load capacity will provide a better ride and likely weigh less than a tire with higher load capacity.

Load Ratings

Each load range has an assigned air pressure identified in pounds per square inch (psi) at which the tire’s maximum load is rated. A Load Range C has a maximum inflation pressure of 50 psi, whereas a Load Range E tire has a maximum inflation pressure of 80 psi. Some new trucks and SUVs come with P Metric tires, which aren’t rated to carry as heavy of loads as Light Truck (LT) tires. P Metric tires are rated as Light Load, Standard Load, and Extra Load. Note that as tires get larger, they often have a lower Load Range. That is different from Load Rating though, which may be higher for a 35-inch Load Range D tire than it is for a 33-inch Load Range E tire. The reason is that a tire’s load capacity is a function of its volume (aka size), construction, and the maximum air pressure it can be inflated to.

A tire’s load carrying capacity is related to the tire’s size and how much inflation pressure is actually used. Maximum loads are rated with the tire inflated to an industry assigned inflation pressure. A tire’s maximum load is the most weight the tire is designed to carry. Note that maximum load rating values are given at maximum inflation pressures. Lower pressures can hold less weight, but provide better ride quality if you are not carrying a lot of weight. Maximum pressures are also listed for a cold tire. As a tire heats up the pressure inside will increase up to 5 psi, but it will decrease as the tire cools off.

Tread Design

Most tires are symmetrical. This means there is not a specific inside or outside to the tire. There is also not a particular direction that you should orient them on your vehicle. Some tires are directional and/or asymmetrical requiring them to be mounted in a specific orientation. A directional tire is one that has differing tread patterns fore and aft. An asymmetric tire has different tread patterns across the face of the tire. Directional tires feature arrows on the sidewall that indicate what direction the tire should rotate when the vehicle is moving forward. Asymmetrical tires have the word “outside” labeled on the side of the tire that should face outward from the vehicle.

Wondering when your tires were made? The last four numbers of the DOT Tire Identification Number are the week and the year that the tire was produced. So, in this case “2814” signifies that this tire was made in the 28th week of 2014. This is particularly important when purchasing used tires. While other factors such as sun exposure are important, we never buy used tires more than ten years old.

M+S denotes a mud and snow tire, which is found on nearly any all-terrain or mud-terrain tire. There is no performance test associated with the M+S designation. The Three Peak Mountain Snowflake (3PMSF) has more stringent requirements and is worth looking for if you do a lot of driving in snow and ice. In fact, in Quebec vehicles are required to run 3PMSF tires from December to March.

DOT Codes

The DOT Tire Identification Number is perhaps the most mystifying piece of information on your tire’s sidewall. DOT stands for Department of Transportation, that part is easy enough. This is followed by 10, 11, or 12 characters such as 73BNP4F2814. These can be used to identify the manufacturing location, tire size, manufacturer’s specifications, and the week and year the tire was manufactured. In this case, “73” is the plant code, “BN” is the tire size, and “P4F” is the tire type. The last four numbers are important though, particularly when buying used tires. “2814” is the month and year that this tire was manufactured. So this tire was made in the 28th week of 2014. The rest of the information is only really useful to us in the event of a tire recall.

UTQG Treadwear and Traction Grades

Many tires will also have a number such as 121/118Q on the sidewall near the tire bead. The first number is the Uniform Tire Quality Grade (UTQG) for treadwear. Tire manufacturers assign a Treadwear Grade based on the observed wear rates over a 400-mile test loop in West Texas run repeatedly to reach 7,200 miles. The higher the UTQG Treadwear number, the longer the tire will last. Note that longer treadwear can translate into less traction on the trail. You need to consider if you are willing to give up performance off-road to have your tires last longer on-road. The second number is the UTQG for traction. This is based on how well the tire can stop in a straight line in wet conditions. It doesn’t evaluate cornering, dry braking, or traction off-road. The last letter is the speed rating of the tire. The higher the letter, the faster you can safely drive on a tire for an extended period. In this case, the Q denotes that the tire is rated for sustained speeds up to 99 mph. Typically the limiting factor for speed rating is how much heat the tire generates, which increases with speed.

Want to know how many plies your tire has? Here it is! Two sidewall plies are the norm for most tires, but three sidewall plies are better for off-road use since they are more resistant to punctures and bruising. Radial tires all use a combination of polyester and steel belts in the tread, but the number of belts can vary.

121/118Q refers to the load rating of the tire. 121 denotes that each tire can carry 3,195 pounds at the maximum inflation pressure. The second number (118) refers to the load rating on a single tire used in a dual rear wheel application. “Q” refers to the tire’s speed rating. In this case, the tire is rated at 99 mph for continuous use. The higher the letter, the faster the tire is rated to travel.

M+S And Three Peak Mountain Snowflake

Three Peak Mountain Snowflake and M+S are critical designations on the sidewall for those that deal with snow. What is the difference between them? The M+S (Mud and Snow) symbol is based on the geometry of the tread design. Originally, it was used to differentiate between a more aggressive bias-ply tire suited for trucks and a passenger car tire. Some manufacturers still use it today. The important thing to remember is that there are no actual performance tests associated with it. Any manufacturer can put M+S on the sidewall of their tire if they want. In reality, the M+S designation doesn’t really mean anything.

The Three Peak Mountain Snowflake symbol looks just like its name. In contrast to the M+S designation, tires with the Three Peak Mountain Snowflake symbol have to pass an actual performance test. One important thing to remember is that this test only measures a tire’s acceleration on medium packed snow. It doesn’t measure braking or turning capabilities. That said, a Three Peak Mountain Snowflake tire is going to perform better than non-rated tires in the snow. But, if you are deep in snow country and deal with lots of the white stuff, a dedicated winter tire is a better choice.

Armed with this information, you can not only impress your friends with your tire knowledge but also ensure that you get the best tires for your specific vehicle and intended use. While you still might be drawn to big, aggressive tires, reading the fine print will help you determine if they are really the right choice for your rig.

10PR is shorthand for 10-Ply Rating, but this radial tire doesn’t actually have ten plies. This designation was developed when bias-ply tires were the norm. A “Load Range E” has a 10-ply rating and a “Load Range C” tire has a 6-ply rating. Higher load ratings generally suggest a stronger tire, but have a stiffer ride.

Have you ever seen painted dots on the sidewall of a tire? Typically a yellow circle, as shown here, indicates where the plies of the tire meet. A red dot is used to denote the heaviest spot on the tire. When mounting tires, align the red dot with the valve stem to minimize the weight necessary to balance the tire.

2